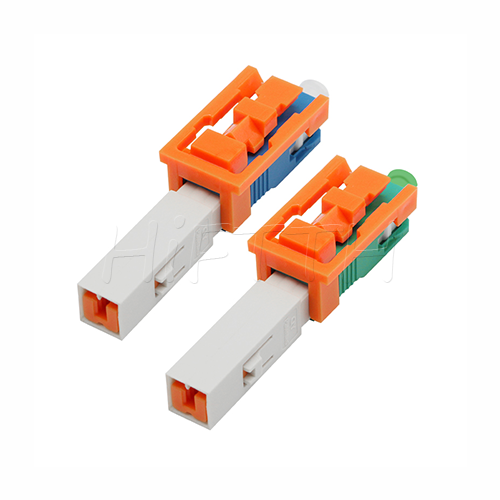

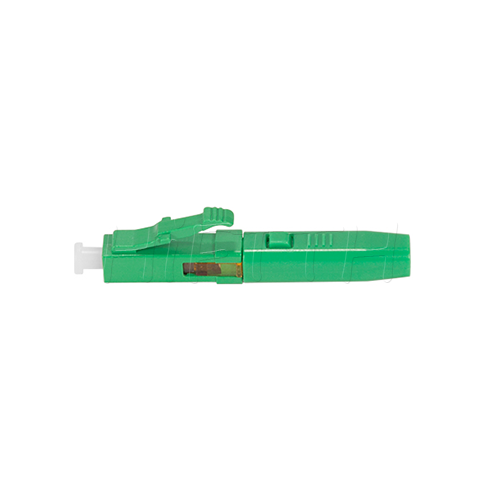

Fiber Optic Fast Connectors, also known as “Field-installable Connectors” or “Quick Connectors,” are a type of fiber optic connector designed for easy and rapid field termination of fibers. They are widely used in fiber optic networks for applications where traditional splicing is not practical or where quick repairs and installations are needed. It is a valuable tool in modern fiber optic networks, offering a quick and effective solution for fiber terminations in various environments.

Their ease of use and minimal tool requirements make them ideal for field installations or emergency repairs, where traditional splicing methods might be too time-consuming or require specialized equipment.

Fast connectors are widely used in FTTH projects for quick and efficient connections at the subscriber’s premises or in outdoor environments.

In data centers, where quick reconfiguration of network layouts might be necessary, fast connectors provide a flexible and speedy solution for modifying fiber optic connections.

They are used for quick repairs or expansions in telecom networks, especially in situations where rapid restoration of service is essential.

For events, demonstrations, or situations where temporary fiber optic connections are needed, fast connectors are a practical choice due to their easy installation and removal.

Advantages

Speed – Quick to install, saving time and labor costs.

Convenience – No need for expensive splicing equipment, ideal for emergency repairs or where splicing is not feasible.

Flexibility – Can be used in a variety of settings and for different fiber types.

Disadvantages

Performance – While very convenient, they may not always match the low loss and high reliability of factory-terminated connectors or fusion spliced connections.

Cost per Connector – Generally, they are more expensive than standard connectors, but this can be offset by the reduced labor and equipment costs.

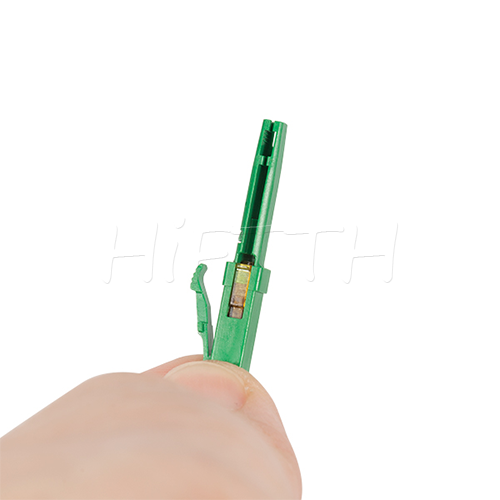

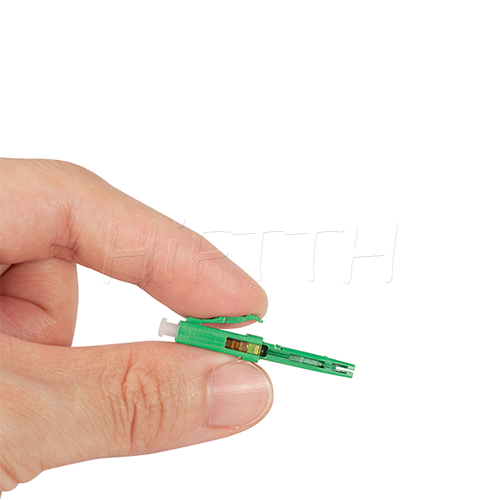

Preparation: The fiber optic cable is prepared by stripping the jacket, removing the buffer coating, and then cleaving the fiber to create a flat, clean end.

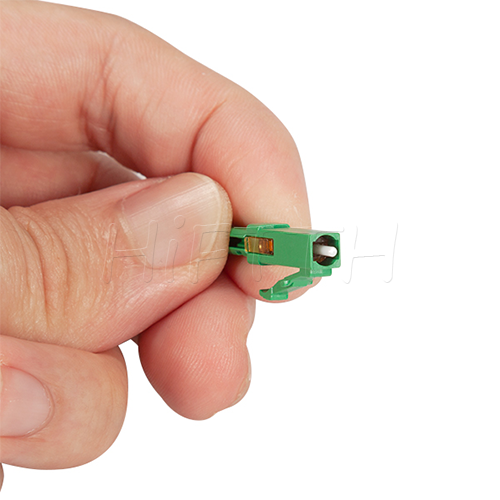

Insertion: The prepared fiber is inserted into the fast connector, which typically contains a pre-polished ferrule and a mechanical splice inside.

Securing the Fiber: The connector often uses a mechanical crimp or a similar method to secure the fiber in place and align it precisely with the pre-polished ferrule.

Index Matching Gel: Many fast connectors use an index matching gel inside the mechanical splice area to help minimize signal loss at the connection point.

Have you see me in the pond ?

Here is more

One-stop Fiber Optic Passive materials of FTTH

Free Samples Available.

Hi!

We will contact you within 1 working day, please pay attention to the email with the suffix “@hiftth.com”.

Come visit our Product Datasheet and discover a product your need.

Leave the Product Type

Be the first to know which Fiber Optic materials 100% meet your need in FTTH solutions.