Fiber optic distribution box is used to manage fiber optic cables and divide them into multiple outputs. They usually contain a splitter, which splits the incoming optical signal into multiple outputs. They are used to distribute signals to multiple devices, such as in a Local Area Network (LAN), and are typically used indoors.

Fiber optic distribution box is a robust, versatile enclosure that facilitates fiber splicing, splitting, and routing in FTTH networks. It ensures physical and environmental protection, organizes fiber connections, and supports network scalability while providing security against tampering, with a capacity to serve multiple subscribers.

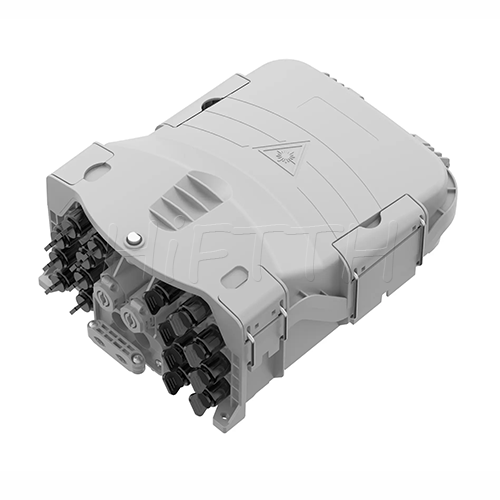

Usually made from high-durability materials like ABS plastic or metal, capable of withstanding environmental stressors such as UV light, moisture, and extreme temperatures.

Shields the internal components from physical damage and environmental factors, ensuring the integrity of the optical connections.

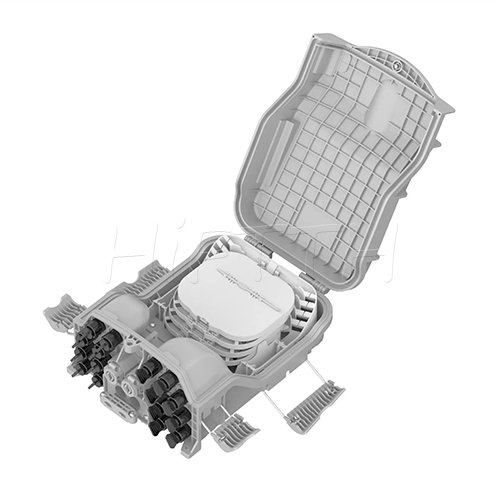

Designed to hold various components like splice trays, splitter cassettes, and adapter panels securely within the box.

Keeps the internal components organized and in place during operation and maintenance activities.

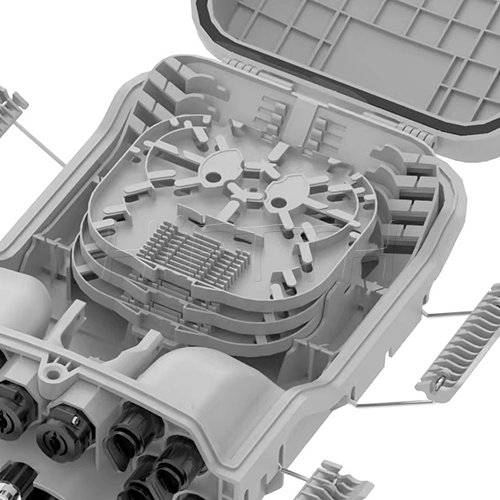

Integrated trays within the box that hold and protect the spliced fiber connections.

Allows for safe and efficient splicing of fiber cables, which is essential for repairing damaged sections or extending the network.

Dedicated slots or cassettes within the box designed to house fiber splitters.

Enables the splitting of optical signals into multiple outputs, allowing a single fiber input to serve multiple subscribers.

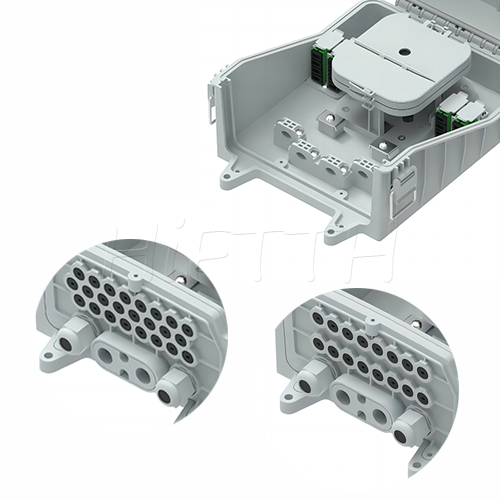

Strategically placed openings or ports for fiber cables to enter and exit the box.

Facilitates the proper routing of incoming feeder cables and outgoing distribution cables, maintaining the necessary bend radius to prevent fiber damage.

A secure cover that can often be locked to prevent unauthorized access.

Protects the internal components from tampering or theft and ensures that only authorized personnel can access the fibers.

Seals and gaskets around openings and covers that prevent water ingress.

Ensures that the internal components remain dry and functional, even when installed in outdoor environments.

Features such as cable glands, anchors, and ducts within the box.

Assists in maintaining a neat and orderly arrangement of cables, which simplifies maintenance and minimizes the risk of damage during handling.

Housings for various types of fiber optic connectors.

Provide the points of interconnection between different cable types and allow for the network to be reconfigured or expanded as needed.

Brackets or mounting points on the exterior of the box.

Enables the box to be securely mounted to a wall, pole, or other structures, ensuring stability and accessibility.

A fiber distribution box is used for managing and distributing fiber optic connections in FTTH networks, housing PLC splitter and adapters, organizing fiber routing, providing environmental protection, and facilitating easy access for network maintenance and scalability.

The production process of a fiber distribution box involves designing the enclosure for environmental resilience, molding the casing from durable materials, assembling internal components like splice trays and splitter cassettes, installing cable management systems, and incorporating security features like lockable covers. Quality checks ensure functionality and protection against environmental factors before distribution.

Have you see me in the pond ?

Here is more

One-stop Fiber Optic Passive materials of FTTH

Free Samples Available.

Hi!

We will contact you within 1 working day, please pay attention to the email with the suffix “@hiftth.com”.

Come visit our Product Datasheet and discover a product your need.

Leave the Product Type

Be the first to know which Fiber Optic materials 100% meet your need in FTTH solutions.