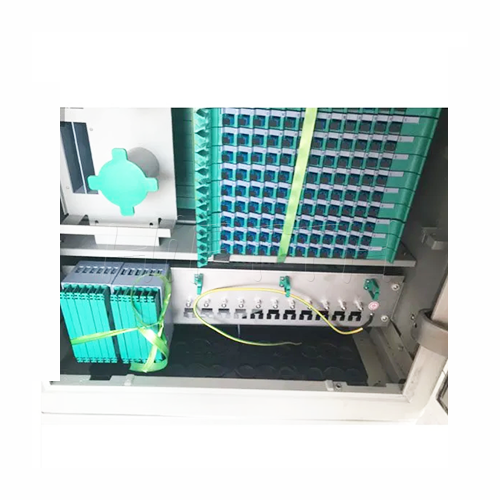

An Optical Distribution Frame (ODF) serves as a central hub in network centers for managing fiber optic connections, facilitating organized cable terminations, splices, and patches, crucial for network configuration and maintenance.

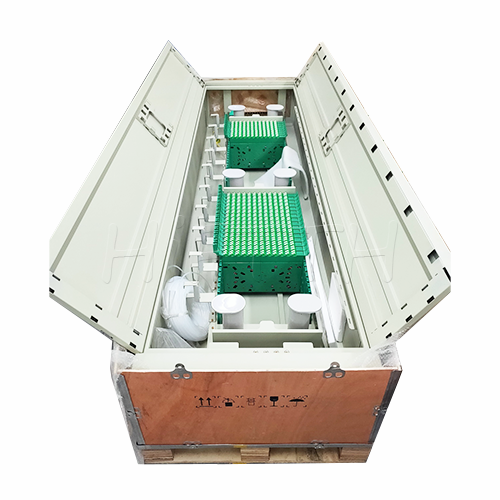

The Outdoor Distribution Cabinet, used on streets, is a robust enclosure designed for outdoor telecom equipment, offering weather resistance and efficient management of street-level fiber connections and cross-connectivity.

Fiber Distribution Frames and Outdoor Fiber Distribution Cabinets, essential in telecommunications, manage and safeguard fiber optic networks. They support cable organization, splicing, and connectivity, crucial for residential and commercial internet and phone services. Designed for scalability and environmental protection, they offer secure, accessible maintenance, ensuring reliable network operation in various settings.

The exterior of outdoor cabinets is often made of impact-resistant materials to withstand physical shocks.

ensures the cabinet can endure physical impacts, like accidental knocks or vandalism, protecting the delicate fibers and connections inside.

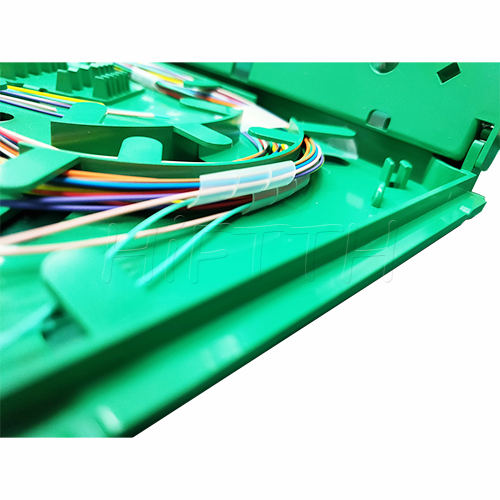

These units sometimes include dedicated areas for excess fiber loop storage.

This helps in managing extra lengths of fiber, ensuring they are stored neatly and safely, which is vital for maintaining signal integrity and minimizing cable stress.

Located at the bottom of the frame or cabinet, this part is where the fiber optic cables enter and leave the unit. It’s designed to hold and protect these cables.

This unit helps guide the cables in and out smoothly, preventing them from bending too much or getting damaged. It keeps the cables safe where they go into and come out of the frame or cabinet.

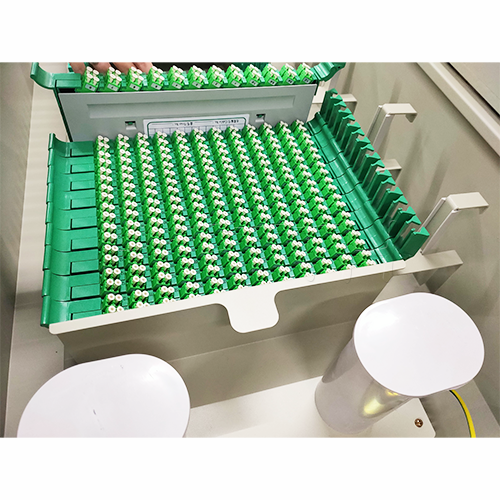

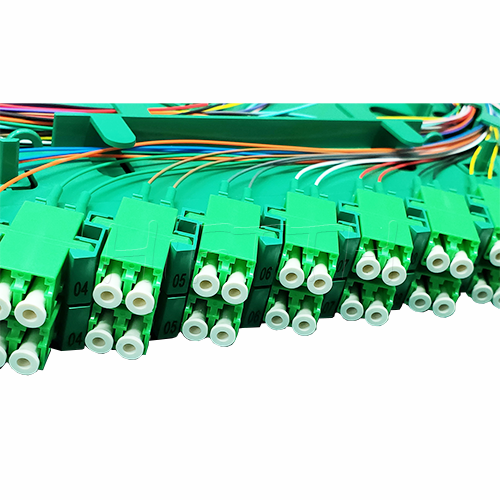

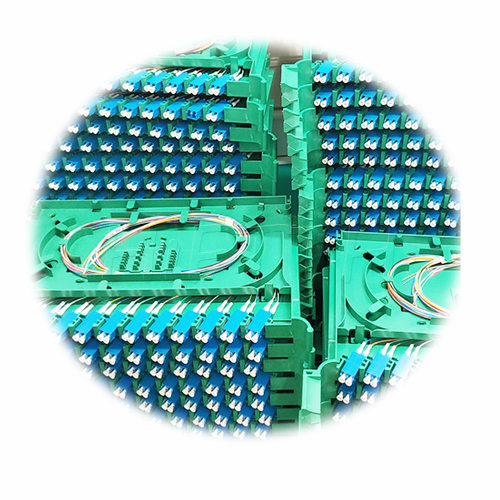

Many frames and cabinets are designed with modular components, allowing for different configurations.

This modular approach enables customization according to specific network needs and allows for easy upgrades or reconfiguration as the network evolves.

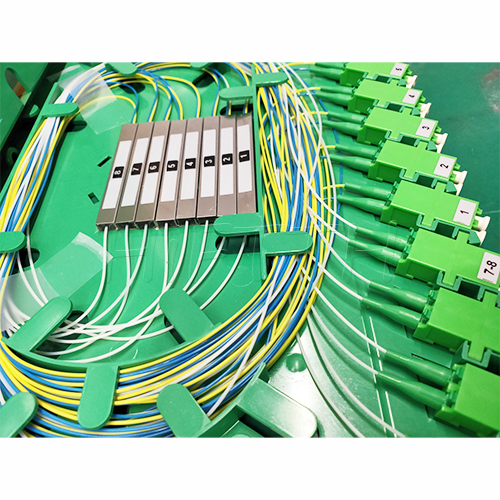

Integrated into the frame or cabinet, this module is specifically designed for both splicing and distributing fiber optic cables

Enables the effective merging and routing of fiber connections, essential for streamlined network configuration and ensuring reliable signal distribution to various endpoints.

Cabinets in FTTH networks might include built-in optical splitters.

These splitters are essential for dividing the optical signal into multiple outputs, facilitating the distribution of services to multiple subscribers from a single fiber.

equipped with locks on their doors to secure access and restrict unauthorized access.

Prevents unauthorized access, vandalism, or accidental damage, ensuring network safety and integrity.

They have special parts for grounding, like metal bars or plates, to connect them safely to the ground.

This grounding helps protect the equipment and people from electrical shocks. It also keeps the fiber optic signals clear by reducing electrical interference.

Features slots or spaces for additional modules or components.

Allows for the expansion of network capacity as demand increases, ensuring the system’s long-term viability.

Includes a clear and organized labeling system on the frame or cabinet.

Facilitates easy identification of cables and connections, streamlining maintenance and network management tasks.

Fiber Distribution Frame (FDF): Engineers design the frame’s enclosure for durability and resilience, molding it from robust materials. They assemble internal components such as splice trays and panels, integrating cable management systems for efficient organization. Security features like lockable covers are incorporated. Rigorous quality checks ensure functionality and environmental protection before distribution.

Outdoor Fiber Distribution Cabinet (ODC): Designers prioritize weatherproofing and ruggedness, selecting materials resistant to outdoor elements. The cabinet’s enclosure is molded with durability in mind. Essential components like splice trays and splitter cassettes are assembled, along with cable management systems. Security measures, including tamper-resistant locks, are integrated. Thorough quality assurance tests validate functionality and resilience to environmental factors prior to distribution.

Have you see me in the pond ?

Here is more

One-stop Fiber Optic Passive materials of FTTH

Free Samples Available.

Hi!

We will contact you within 1 working day, please pay attention to the email with the suffix “@hiftth.com”.

Come visit our Product Datasheet and discover a product your need.

Leave the Product Type

Be the first to know which Fiber Optic materials 100% meet your need in FTTH solutions.