Fiber optic closures are protective enclosures used in various network types, including transport, metropolitan, FTTx, and PON. They feature IP68 protection and accommodate direct splicing of fibers or to fiber optic splitters. Installation can be in cable chambers, underground, or mounted on poles or walls. Key considerations for selection include aerial vs. buried placement, in-line vs. butt, port counts, and cable diameter. These closures protect optical fiber splices and connectors from different cables, such as feeder, branch, drop, ribbon, loose tube, and microcables. Constructed with weather-resistant shells and fiber managers, they can be installed Man-hole, in aerial settings, or wall-mounted.

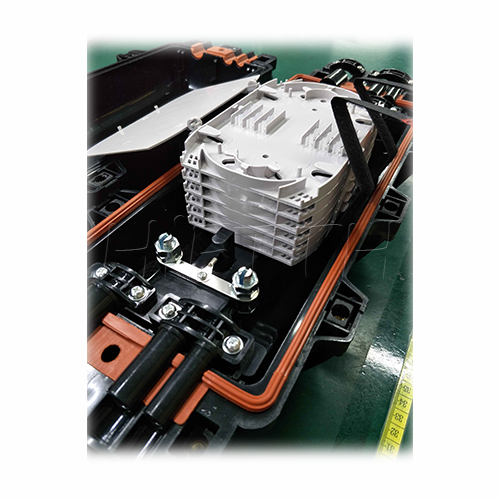

A fiber optic splice closure is a durable enclosure for splicing and managing fiber cables in telecommunication systems. It provides robust environmental protection, supports various cable capacities, and is made from high-strength, corrosion-resistant materials. Its scalable design and comprehensive accessories ensure efficient network operation and expansion.

Typically made from high-strength materials like reinforced plastic or metal, designed to endure harsh environmental conditions including UV exposure, temperature extremes, and moisture.

Provides a robust barrier against external elements, ensuring the long-term integrity and performance of internal fiber connections.

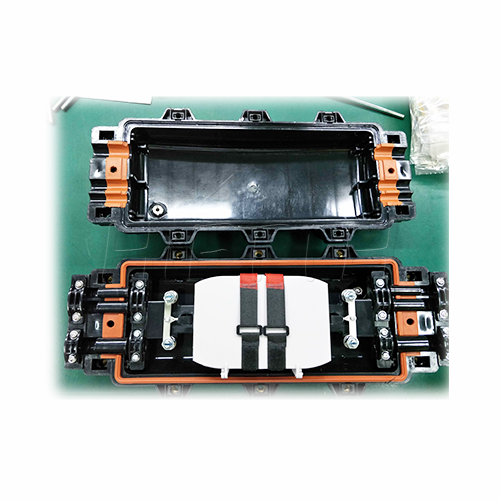

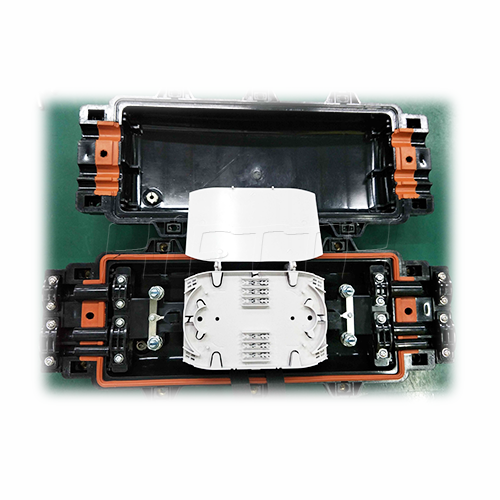

Trays or compartments within the closure for securely holding and organizing spliced fibers.

Facilitates precise and protected splicing of fibers, ensuring effective alignment and connection while preventing entanglement and stress on the fibers.

Internal design features such as guides or channels specifically shaped to ensure that fibers are laid out with proper bend radius.

Prevents excessive bending of the optical fibers, which is critical for maintaining signal integrity and preventing fiber damage, especially important in environments with frequent adjustments or in high-density splicing situations.

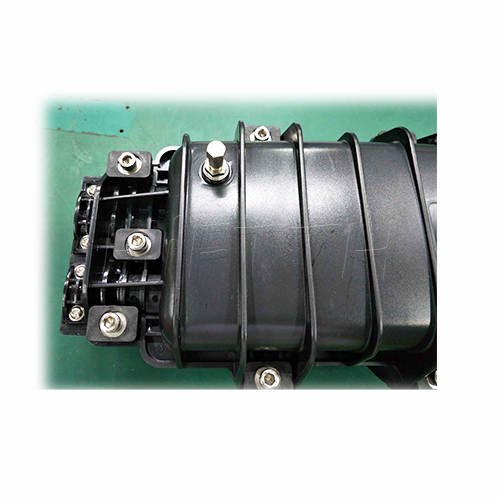

Robust seals, typically made of rubber or similar materials, that are integrated into the closure.

Ensures a watertight and dustproof environment for the delicate fiber connections, crucial for maintaining signal integrity.

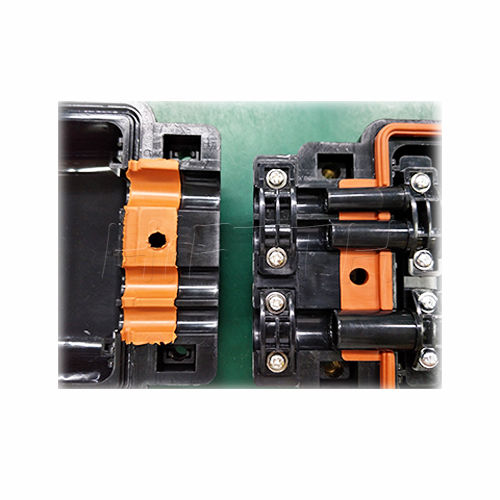

Entry and exit points engineered to accommodate various types and sizes of fiber optic cables.

rovides structured and secure entry and exit pathways for optical cables, maintaining proper bend radius and protecting cables from strain.

A lockable lid or access panel, often requiring tools or keys for opening.

Prevents unauthorized access and tampering with the internal fiber connections, maintaining network security.

Seals and gaskets around openings and covers that prevent water ingress.

Ensures that cables are firmly anchored, reducing strain and risk of disconnection or damage, particularly in outdoor or high-movement environments.

A small, specialized valve integrated into the closure’s body.

This valve helps to equalize internal and external pressure, particularly important in preventing condensation inside the closure and in maintaining seal integrity during temperature and altitude changes. It’s especially useful in outdoor or varying environmental conditions, ensuring long-term protection of the fiber connections.

A designated space within the closure specifically for accommodating excess lengths of loose tube fibers.

This area allows for the storage of extra lengths of fiber, providing redundancy and flexibility for future network adjustments or repairs. It ensures that there is sufficient slack for re-routing or re-splicing fibers without the need for additional cabling, thereby enhancing the closure’s adaptability and serviceability over time.

Exterior brackets or points for secure installation.

Allows for stable and accessible mounting on walls, poles, or other structures.

A fiber splice closure is used for securely protecting fiber optic splices, organizing cables, ensuring environmental resistance, managing cable entries and exits, and providing scalable, adaptable connectivity in fiber optic networks.

The production of a fiber optic splice closure involves designing for environmental resilience, selecting durable materials, molding the casing, assembling internal components like splice trays, ensuring cable management, sealing for waterproofing, adding security features, conducting quality checks, and finally packaging for distribution.

Have you see me in the pond ?

Here is more

One-stop Fiber Optic Passive materials of FTTH

Free Samples Available.

Hi!

We will contact you within 1 working day, please pay attention to the email with the suffix “@hiftth.com”.

Come visit our Product Datasheet and discover a product your need.

Leave the Product Type

Be the first to know which Fiber Optic materials 100% meet your need in FTTH solutions.